We are Leading Plastic Raw Material Manufacturer

TNC-INC is a leader in the production of high-performance recycled plastic granules,

dedicated to driving the circular

economy in India. We transform plastic waste into certified, reliable raw materials,

enabling industrial businesses to

achieve their sustainability goals without compromising on product quality.

Products

Happy Customers

satisfaction

Global Presence

TNC is dedicated to transforming plastic waste into high-quality, reliable raw materials. We offer more than just a product; we offer a sustainable, professionally managed supply solution designed for your manufacturing excellence.

Rigorous lab testing ensures uniform product performance meeting all global technical standards.

We ethically source plastic scrap, driving the circular economy and providing a greener raw material.

Strong logistics and inventory management guarantee hassle-free, on-time delivery of every granule order.

We offer customized compounding and flexible solutions tailored to your unique business challenges.

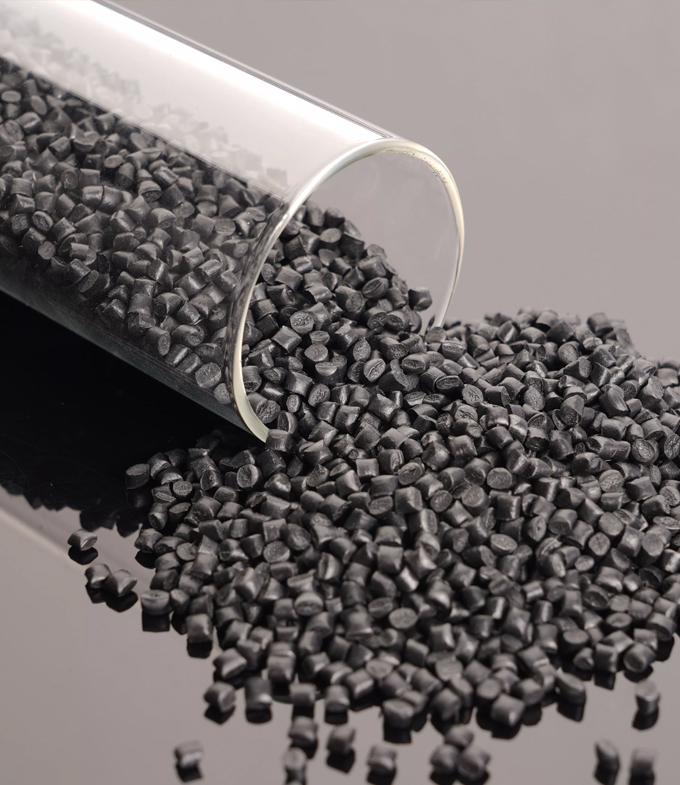

The manufacturing process of plastic granules typically involves key steps like polymerization, extrusion, and pelletization, which are used to create the small, uniform particles essential for a wide range of applications:

This is the foundational step where chemical reactions between monomers form long polymer chains. These chains determine the properties of the plastic, such as strength, flexibility, and resistance to temperature.

Step - 01

The polymer is melted and fed into an extruder, where it is shaped into continuous strands. These strands are then cooled and prepared for further processing.

Step - 02

The extruded plastic strands are cut into small, uniform pieces called granules. These granules may undergo additional treatments, such as coloring or strengthening, depending on their intended use.

Step - 03